![]()

Tutorials:

The Edge

| If you're like me, you sometimes get obsessed by a potentially gorgeous new knife design or the thought of a new handle material and you sometimes forget the whole point of this exercise we call knifemaking. When you think about it, the whole purpose is to come up with an attractive way to carry that part of the knife that does all of the work: the edge. And while the rest of this web site will try to help you make a nice looking knife, this page will try to help shed some light on this most misunderstood component of the blade. |

Click on any of the thumbnails below for a more detailed photo

|

|

OK, so why can't you shave yourself with an axe? (Actually, you might be able to by the end of this tutorial). So what's the difference between the edge of a machete and an Xacto blade? The answer, quite simply, is geometry. Yeah, it all comes down to the angle. Let's take a closer look. | |

| The difference between an axe and an Exacto blade is, to oversimplify, the angle of the edge. An axe may have an angle on the edge of around 30 degrees while the Exacto blade may have an angle of around 11 degrees. Starting to see why the Exacto blade cuts more aggressively and cleanly? | ||

| Not that axe edges are bad. They're designed to split, not necessarily cut. The edge acts as a wedge to force the wood apart. Shaving ( or the cutting function of a knife blade) is a totally different function. Whereas an axe splits, a very sharp blade would only become wedged and stuck. | ||

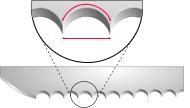

| Since smaller angles make sharper edges, you can see why hollow grinding is popular. These pictures are naturally exaggerated, but you can see the difference. Flip side of the coin, since there is less metal on the edge, they do seem to dull a little more quickly. | ||

| Taking an even closer look, we find that there is a secondary grind right at the very cutting edge of the knife. This is called the secondary bevel, and this is what actually does the cutting. You're going to have to look very close since this could be very tiny. | ||

| The secondary bevel is the part of the edge that is sharpened. It is all important to make sure, when sharpening, to make sure that you are matching this angle . It's a common mistake to get this angle wrong and then wonder why you spent so much effort and the blades not getting any sharper: it's because you haven't touched the edge! | ||

| But if you do follow through, increasing the able of the secondary bevel as you sharpen, you will end up with a much more aggressive edge that will be shaving sharp. This is also why you can always improve on the edge of a new factory made knife | ||

| You should also know about the burr: as you sharpen the blade, the edge will get thinner and will eventually result in an edge that is about as thick as a piece of tin foil and starts to turn up. It's small enough that you may not be able to see it, but you can feel it by running your finger from the back of the blade over the front. This is when to stop. Flip the blade and just give it a few swipes, enough to get rid of the burr. Your blade is now very very sharp. | ||

| Over time, many sharpenings can actually change the shape of your blade since you are removing a little bit of metal every time. Most of the time, all you really need to do is to touch up the secondary bevel. Don't overdue it. | ||

| It'll never be a mirror polished edge. Now we're down to about a 10,000 magnification and we can see the saw tooth edge left by the abrasive action of the sharpening. Not a bad thing. This will actually give it a very aggressive slicing action. The finer the final abrasive that you use on the edge, the smaller the "sawteeth" will be. | ||

| Another reason that people sometimes think their blade may be dull is that that the edge, because of the angle of the secondary bevel, may actually be preventing the edge from contacting the surface that you're cutting. This is pretty common with "factory" edges. | ||

|

So what are these angles we keep referring to? (To be continued) |

||

|

Straight

versus Serrated Edges: Which is better? This is the subject of a debate that's been going on forever and there are probably entire websites devoted to both sides of the argument. If you put two knifemakers together, you'll get three opinions. Let's try to analyze this logically. First, let's start off by stating the obvious: Serrated edges are not sharper. If they were, your shaving razor would have a serrated edge. It doesn't. |

|

| Let's start off with what you're going to use your knife for: a knife can either provide a slicing or sawing function. If you, say for instance, cut a lot of rope, I can see where the serrated edge would give you more of a sawing action and provide greater efficiency. Proponents of serrated edges claim that the shape of the edge "grabs" better but if you test this objectively, it's pretty darn near impossible to notice any difference. Bread knives used on hard crusted breads work better with a serrated edge | ||

|

Proponents of serrated edges claim that the shape increases the surface area of the cutting edge. This is a logical and persuasive argument but again, in real life tests, the benefits are pretty darn hard to notice. I'm sure there's a simple mathematical formula to figure this increase in cutting surface area. I'll have to ask one on my kids. | |

|

Serrated edges were originally designed for restaurants and steak houses where the edge would be in constant action against a hard ceramic plate. The serrations are designed to hold the cutting edge away from the plate so that these don't need to be resharpened daily. Only the tips of the serrations come in contact with the plate. This is probably, in my mind, the most persuasive argument for the usefulness of serrated edges. | |

| Serrated edges also have a reputation for being hard to sharpen. Yes, it takes more work, but it can be done. A lot of quality knives have their serrations ground on one side only. Simply sharpen these from the back, non-serrated side of the blade. If you do need to sharpen between the teeth of the serrations, it's not hard to use a small round or triangular file or ceramic sharpening stick. Several manufacturers make these. Since the serrations are so small, I'd suggest doing this under some sort of magnifier. Here's another good picture. Click HERE | ||

| Let's not discount aesthetics . I have to admit that on some knives, the serrated edge adds a very aggressive look. I suspect that most of the arguments about serrated versus straight edges really involve more of their look than function. This is a picture of SOG's Seal Pup, one very sexy looking knife. See what I mean? | ||

|

I think a lot of the confusion on serrated edges comes from the poor reputation that comes from the all too common serrated kitchen knives ( stereotyped by the "Ginsu"). The manufacturers of these seem to hope that most people will confuse their sawing ability with sharpness . I've got a few and I like them but when they get dull, I consider them disposable. | |

| Can you add your own serrations to a straight edged knife? Sure, why not? Use a fine tipped magic marker to mark your pattern and use a round diamond. I'd recommend an Optivisor or magnifying lamp while doing this, since this is going to be some fine detailed work. I guess you could use a rotary grinding bit on a Mototool also. |